Electrical resistance heating is a process that uses electricity to heat up a material. The heat is generated by the resistance of the material to the flow of electricity. Electrical resistance heating machines are used in a variety of industries, including manufacturing, food processing, and healthcare.

Different Types Of Electrical Resistance Heating Machines

There are many different types of electrical resistance heating machines, each with its own advantages and disadvantages. Some of the most common types include:

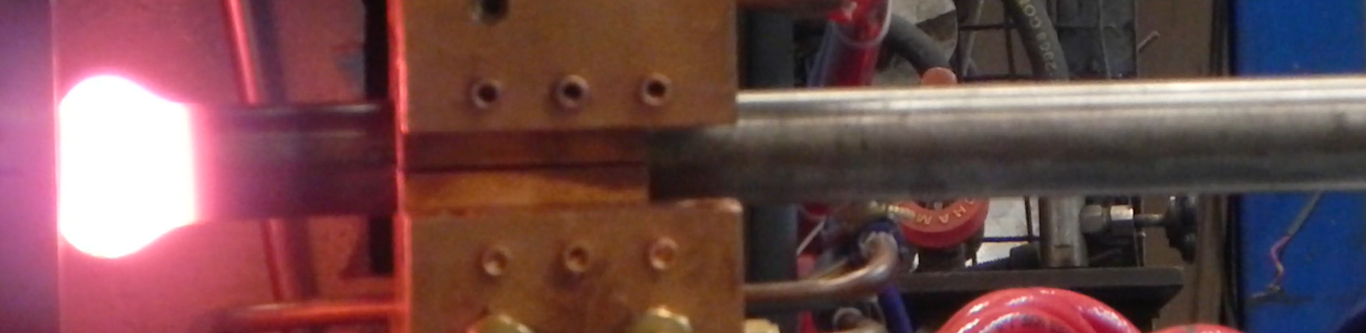

- Ohmic heating: This is the most basic type of electrical resistance heating. It works by passing an electric current through a material, such as a wire or metal strip. The resistance of the material to the flow of electricity causes it to heat up.

- Induction heating: This type of heating uses a magnetic field to heat up a material. The material is placed in a coil that is energized with an electric current. The magnetic field generated by the current causes the material to heat up.

- Dielectric heating: This type of heating uses high-frequency alternating current to heat up a material. The material is placed between two electrodes and the alternating current is applied. The dielectric properties of the material cause it to heat up.

How Electrical Resistance Heating Machines Work

The basic principle of electrical resistance heating is that when an electric current flows through a material, the material heats up. The amount of heat generated is proportional to the square of the current and the resistance of the material.

The resistance of a material is determined by its resistivity, which is a measure of how difficult it is for electricity to flow through the material. The resistivity of a material is affected by its temperature, so the resistance of a material will increase as it heats up.

Factors to consider when choosing an electrical resistance heating machine

When choosing an electrical resist ance heating machine, there are several factors to consider, including:

- The type of material you need to heat

- The amount of heat you need to generate

- The size and shape of the material

- The budget you have

- The safety requirements of your application

Applications Of Electrical Resistance Heating Machines

Electrical resistance heating machines are used in a variety of industries, including:

- Manufacturing: Electrical resistance heating machines are used to heat materials in a variety of manufacturing processes, such as welding, brazing, and soldering.

- Food processing: Electrical resistance heating machines are used to cook food, sterilize food, and melt chocolate.

- Healthcare: Electrical resistance heating machines are used to heat medical equipment, such as surgical instruments and IV bags.

- Other applications: Electrical resistance heating machines are also used in a variety of other applications, such as shrink wrapping, plastics welding, and thawing frozen food.

Benefits Of Using Electrical Resistance Heating Machines

Electrical resistance heating machines offer a number of benefits, including:

- They are efficient and can heat materials quickly.

- They can be used to heat a variety of materials.

- They are relatively easy to operate and maintain.

- They are available in a variety of sizes and configurations to meet the needs of different applications.

Safety precautions when using electrical resistance heating machines

Electrical resistance heating machines can be dangerous if not used properly. It is important to follow the safety precautions that come with the machine, such as:

- Always wear safety glasses when operating an electrical resistance heating machine.

- Make sure the machine is properly grounded.

- Do not touch the machine while it is in operation.

- Be aware of the potential for electrical shock.