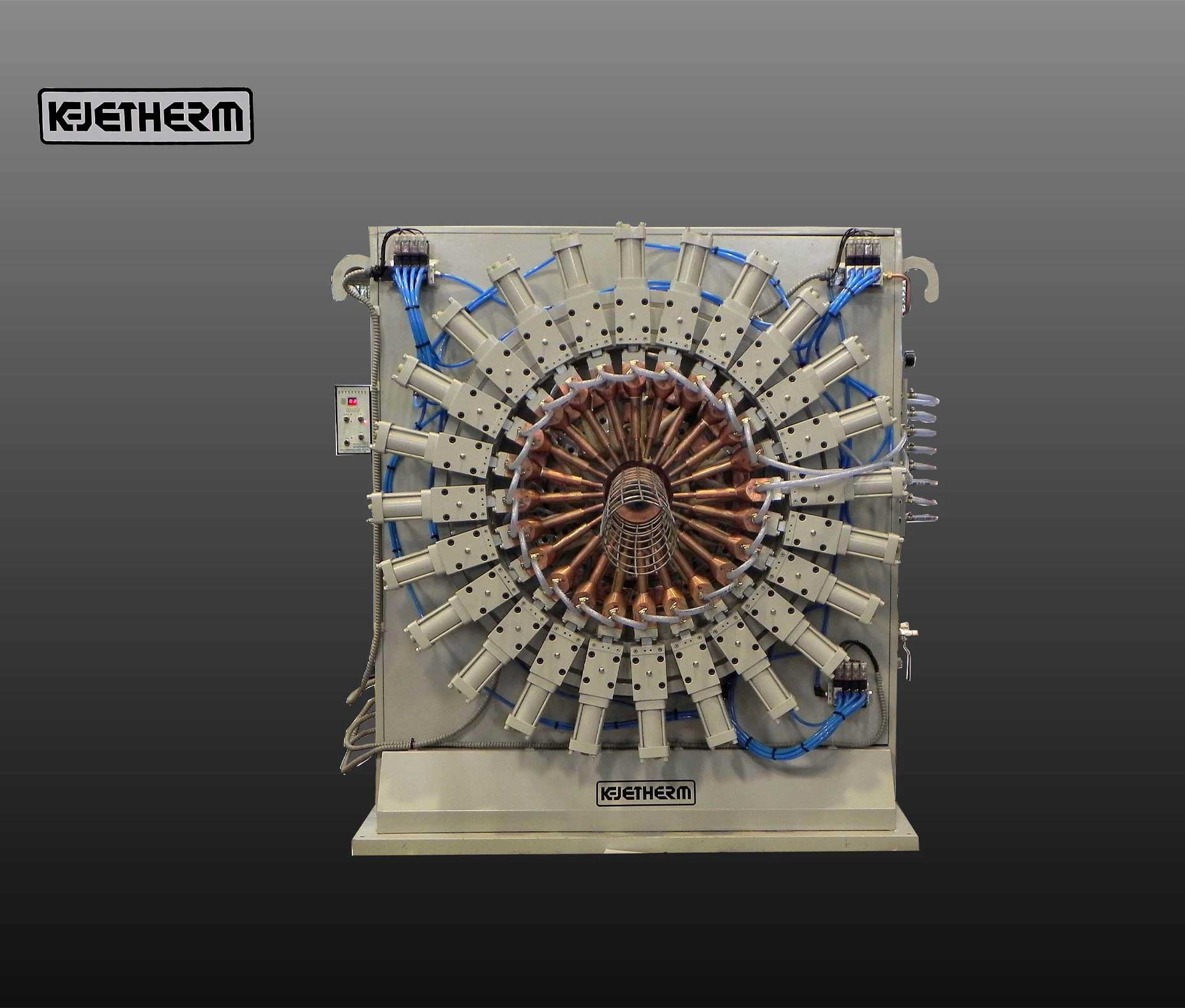

Keje Thermoweld Equipment, your trusted Multi Spot Welding machine manufacturers, suppliers, exporters in Delhi. Our commitment to precision and innovation sets us apart in the welding industry.

Our Multi Spot Welding machines in Delhi are engineered to deliver superior performance and durability, making them ideal for a wide range of applications. Whether you’re in automotive, aerospace, or any industry that demands spot welding precision, we have the solution for you.

With advanced technology and a focus on quality, Keje Thermoweld’s Multi Spot Welding machines ensure consistent and reliable welds, maximizing efficiency and productivity. Explore our range of welding solutions and experience the future of spot welding machines with us.

What is Multi Spot Welding Machine?

A Multi Spot Welding machine, also known as a multiple spot welder or spot welding station, is a specialized welding equipment used in various industries for joining metal components together. It works by applying a series of spot welds at multiple points on the surface of the metals to create a strong and permanent bond.

How to use Multi Welding Machine?

- Material Preparation: Ensure that the metal components you want to weld are clean and properly aligned. Proper preparation of the materials is crucial for a successful weld.

- Machine Setup: Set up the Multi Spot Welding machine according to the specific requirements of your welding project. This may involve adjusting the welding parameters such as welding current, time, and electrode pressure.

- Positioning: Place the metal components to be welded in the desired position within the machine. Ensure that they are in contact with the welding electrodes.

- Welding Process: Activate the machine, and it will apply a series of rapid electrical pulses to create spot welds at predefined points on the metal surfaces. The intense heat generated by the electrical current melts a small area of the metals, fusing them together.

- Cooling: After welding, allow the welded area to cool down gradually. Cooling time may vary depending on the materials and welding parameters used.

- Quality Check: Inspect the welds for quality and integrity. Multi Spot Welding typically produces strong and consistent welds, but it’s essential to ensure that the welds meet your project’s requirements.

Our Multi Spot Welding machines are versatile and can be used in various applications, including automotive manufacturing, appliance production, electronics, aerospace, and more. These are particularly valuable for joining thin sheets of metal, providing a reliable and efficient method for creating strong, durable connections.

Specification

| Range dia | ID 110 to 160 mm |

| No of wires | 8 to 24 |

| Production | 40 cages to 120 cages per shift |

| Power required | 30 to 214 KVA |

| Length | 3500mm to 6000 mm |