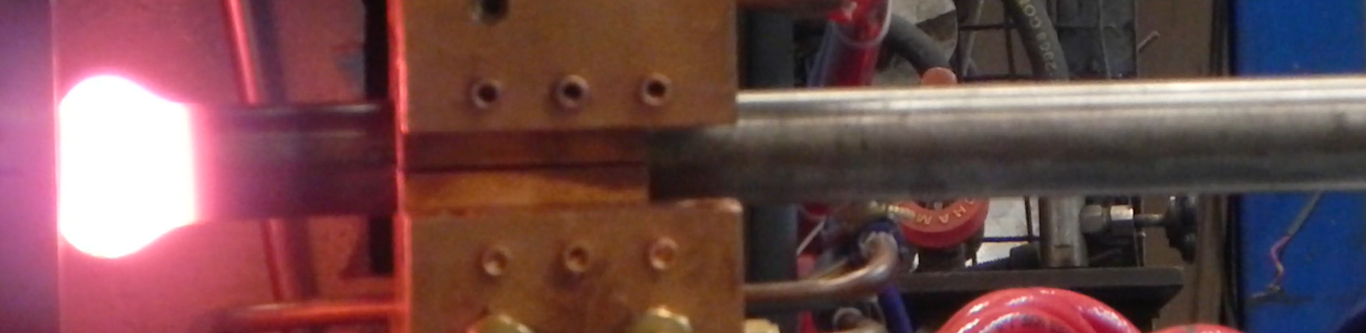

Welcome to Keje Thermoweld Equipment, your leading Electrical Upsetting Machine manufacturers, suppliers, exporters in Hyderabad. We specialize in providing top-quality solutions for electrical Upsetting Machine in Hyderabad.

Our Electrical Upsetting Machine is engineered for precision and versatility. Whether you’re in the business of forging bolts, screws, or other metal components, our machine offers unmatched control over the upsetting process, ensuring consistent results with tight tolerances.

Powered by advanced electrical and hydraulic systems, our Upsetting Machine is designed to meet your specific manufacturing needs. With a commitment to quality and reliability, Keje Thermoweld is your partner for excellence in metal forging. Explore our range of welding machines today to elevate your production capabilities.

What is Electrical Upsetting Machine?

An Electrical Upsetting Machine is a specialized industrial equipment used for the forging process, primarily in the manufacturing of metal components. Here are the features of an Electrical Upsetting Machine: -

- Upsetting Capability: The primary function of this machine is to upset or increase the cross-sectional area of a metal workpiece by subjecting it to high axial compressive forces. This process is commonly used to form the heads of bolts, screws, and other fasteners.

- Electrically Driven: Unlike traditional mechanical upsetters, an Electrical Upsetting Machine is powered by electricity, typically with a motor and hydraulic or pneumatic systems for precise control of the forging process.

- Precision Control: These machines offer precise control over the forging process, allowing manufacturers to produce components with consistent dimensions and quality. This is crucial in industries where tight tolerances are required.

- Versatility: Our Electrical Upsetting Machines can handle a variety of metal materials, including steel, aluminum, and brass. They are adaptable for different forging applications and can accommodate various workpiece sizes and shapes.

How to use an Electrical Upsetting Machine?

- Prepare the Workpiece: Ensure the metal workpiece is properly cleaned, cut to the desired length, and placed securely in the machine’s gripping mechanism.

- Set Parameters: Adjust the machine’s settings, including the upset length, forging force, and speed, according to the specifications of the desired component.

- Start the Machine: Activate the machine’s electrical and hydraulic systems to initiate the forging process. The machine will apply axial pressure to the workpiece, causing it to upset and form the desired shape.

- Monitor the Process: During operation, closely monitor the machine to ensure that the forging process is proceeding correctly. Adjust settings as needed to maintain quality and consistency.

- Remove and Inspect: Once the forging process is complete, remove the formed component from the machine and inspect it for quality and dimensional accuracy.

FAQs

1. What is an electrical Upsetting machine?

Answer: An electrical Upsetting machine is a forging equipment that uses electrical power to upset or reshape the ends of metal workpieces for various applications.

2. What types of materials can be processed with an electrical upsetter?

Answer: Electrical upsetters are versatile and can be used with materials like steel, aluminum, and other metals suitable for forging processes.

3. What are the advantages of using an electrical upsetter?

Answer: Electrical upsetters offer advantages like precise control over the forging process, increased production speed, improved material utilization, and reduced waste.

4. What industries commonly use electrical Upsetting machines?

Answer: Our Electrical Upsetting machines are commonly used in automotive manufacturing, aerospace, construction, and metalworking industries for producing high-strength components like bolts, fasteners, and connecting rods.