Keje Thermoweld Equipment is the leading Metal Gathering machine manufacturers, suppliers, exporters in Delhi.

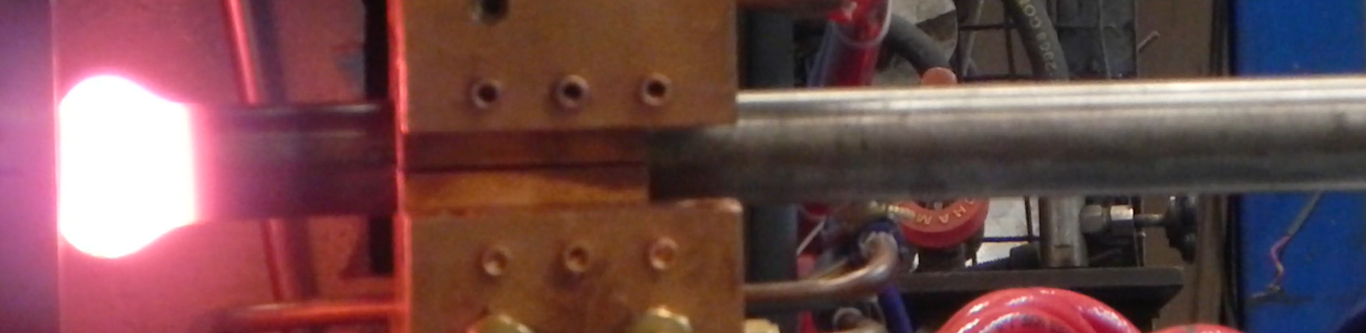

A metal gathering machine is a machine that uses resistance heating to join two metal pieces by melting and then forcing the molten metal together. The heat is generated by an electric current passing through the metal, and the pressure is applied by the machine's electrodes. It is a versatile machine that can be used to join a variety of metals, including steel, aluminum, and copper.

How does a metal gathering machine work?

The metal gathering machine works by passing an electric current through the metal to be joined. The current creates a heat that melts the metal at the point of contact. The pressure of the machine's electrodes then forces the molten metal to fuse together.

The amount of current and pressure used in the metal gathering process depends on the thickness of the metal being joined, the desired weld strength, and the speed of the welding process.

Metal Gathering Machine Properties

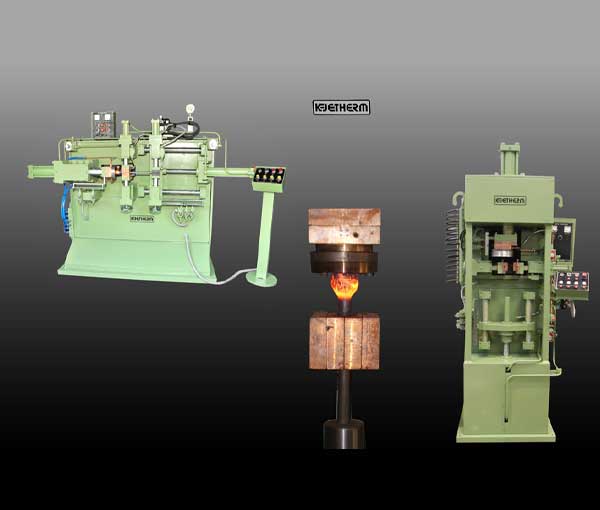

- Robust Construction: Heavy-duty machines are built with sturdy materials, such as cast iron or steel, to withstand the high forces and vibrations associated with metalworking.

- High Power: These machines are equipped with powerful motors and mechanisms capable of handling large and dense metal workpieces.

- Precision: These machines often feature precise controls and adjustments to achieve accurate cutting, shaping, or forming of metal components.

- Versatility: Our Heavy-duty machines come in various types, including lathes, milling machines, and press brakes, making them adaptable to a wide range of metalworking processes.

Common uses of Metal Gathering Machines

- Metal Cutting- These machines can be used for cutting, shearing, and shaping metal sheets, rods, or pipes into desired shapes.

- Machining- These machines are crucial for precision machining operations like drilling, milling, and turning metal parts to specific dimensions.

- Metal Forming- Our Heavy-duty machines are employed for processes such as bending, stamping, and forging to create complex metal components.

- Welding Preparation- It can be used to prepare metal surfaces, ensuring proper fit and alignment before welding.

- Heavy Fabrication- In industries like shipbuilding or construction, heavy-duty machines are used for working with thick and large metal structures.